|

|

|

|

|

Shanghai Office

Tangshan Road, Yangpu District, Shanghai, China, Lane 1188

No. 15-203

Tel: 86-21-35013958

Fax: 86-21-33817303

Zip Code: 200092 |

Arrow techno Co., Ltd.

Shibuya Ward, Tokyo, Japan Shibuya 3-chome 17, No. 1 Fan

Phone: 81-03-54660381

Fax: 81-03-54660385 |

|

| |

|

| |

|

| |

|

|

|

|

|

|

|

| Chip processing is time consuming and the visibility is poor with cutting oil…

Arrow techno collectively solves the problem related to the chip processing and the working environment in plants.

|

|

|

orries of Company A |

|

| Automate chip processing, efficient recycling and plant cleanliness |

Industry Category: Auto parts processing industry

The processing objects are such as Aluminum, cast iron, and difficult-to-cut materials etc.

Scale: Domestic manufacturing base at three locations, and about 1,000 employees |

| Company A is engaged in processing of auto parts from several decades, and a wide range of machineries have been installed in their existing plant. For diverse materials, the processing and extraction of chips and wastage have been allocated to their respective workforce. For example, 5 people were allocated in “B Plant” for chips extraction, and they had been doing it manually by getting the same loaded in such as trolleys etc. The automation of chip processing remained a challenge for many years as extracted ones may fall and overturn with manual handling. There used to be a useless disposal, as the cutting oil can not be separated though some of the chips can also be reused. The great amount of wastage is also a problem. Moreover, the coolant becomes mist in the air during the process from processing till disposal; and the poor visibility in the plant resulted as a problem in the working environment. Thus, this time, a new set up of plant is assumed as a favorable opportunity, and a centralized chip processing system was decided to be installed in the new plant. |

|

Our offerings |

|

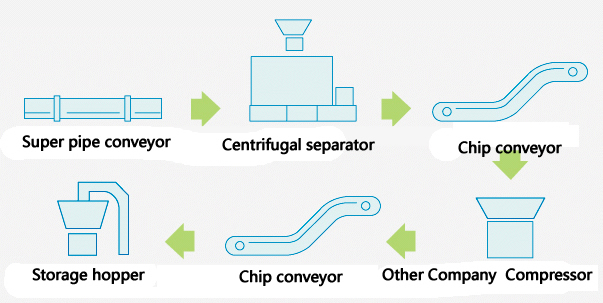

| The following four proposals were made to Company A:

“Centralized Processing Equipment” to deal with scrap from cutting operations

Transportation by the pipe conveyor

Centrifugal separator

Chips compressor

The labor saving cannot be achieved just by getting the chip processor installed. Our own products and the products of our partner companies are used in accordance with the plant environment and the processing conditions of the customer; and the chip processing in the plant was completely proposed. The pipe conveyor was proposed to transport chips being extracted from the processing machine. The automation and, simultaneously the clean conveyance are achieved, since the case of this conveyor carries contents by the pipe in a sealed condition. The centrifugal separator, separated the transported chips from the cutting oil, and reduced the consumption of capacity in the chip compressor. Also, the recycling in an efficient manner and an easy disposition are possible with our centrifugal separator since it has high de-oiling rate. |

|

|

Achievements and Customer’s comments |

|

| The reduced labor cost and the environmental reformation make further growth possible. |

The employees engaged in the chip processing were five in the old plant now controlled to less than 2 employees in the new plant, thus resulted in reduced labor cost. The rest of the employees will be able to spare the employees engaged in production and development.

The good quality resources could now be recruited and assigned by having the plant environment maintained. Also, the risk such as industrial/ work related accidents can be reduced. When anyone consults with our company at the time of installation; almost there is no burden on the user since we undertake all coordination concerning with the equipment.

We consider this as a path for manufacturing industries to survive when excellent resources are recruited, and growth is achieved by putting efforts in research and development because it is not an era of just selling-off the products if they are made in large quantities. There might be initial cost involved when the chip processing system is installed, but the reduced labor cost and efficient operations might recover the same in few years. |

|

|

|